Bisa ga bincike da bincike, lalata na ɗaya daga cikin muhimman abubuwan da ke haifar da lalacewa ga bawul ɗin malam buɗe ido.Domin rami na ciki yana hulɗa da matsakaici, yana da lalata sosai.Bayan lalata, diamita na bawul ya zama karami kuma juriya na kwarara yana ƙaruwa, wanda ke rinjayar watsawar matsakaici.Ana shigar da saman jikin bawul ɗin a ƙasa ko ƙarƙashin ƙasa.Fuskar tana cikin hulɗa da iska kuma iska tana da ɗanshi, don haka yana da saurin yin tsatsa.An rufe wurin zama na bawul gaba ɗaya inda rami na ciki ke cikin hulɗa da matsakaici.Sabili da haka, jiyya na gyaran fuska na jikin bawul da farantin bawul shine mafi kyawun hanyar kariya mai tsada akan lalata a cikin yanayin waje.

1. Matsayin malam buɗe ido bawul surface shafi

01. Valve jikin kayan ganowa

Ana amfani da launi mai launi na saman zuwa saman da ba a sarrafa ba na jikin bawul da bonnet.Ta hanyar wannan alamar launi, za mu iya sauri ƙayyade kayan jikin bawul kuma mu fahimci halayensa.

| Valve Jikin Material | Launi mai launi | Valve Jikin Material | Launi mai launi |

| Bakin Karfe | Baki | Iron Ductile | Blue |

| Karfe Karfe | Baki | WCB | Grey |

02. Tasirin garkuwa

Bayan an rufe saman jikin bawul da fenti, yanayin jikin bawul ɗin yana da ɗan bambanta da yanayin.Ana iya kiran wannan sakamako na kariya da tasirin kariya.Duk da haka, dole ne a nuna cewa fenti na bakin ciki ba zai iya samar da cikakkiyar tasirin kariya ba.Saboda polymers suna da wani nau'i na numfashi, lokacin da rufin ya kasance mai bakin ciki sosai, ramukan tsarin yana ba da damar ruwa da kwayoyin oxygen su wuce kyauta.Soft-sealing bawuloli suna da tsananin bukatu a kan kauri na epoxy guduro shafi a saman.Don inganta rashin daidaituwa na suturar, maganin rigakafi ya kamata a yi amfani da abubuwa masu samar da fina-finai tare da ƙananan iska da ƙwaƙƙwarar filaye tare da manyan kayan kariya.A lokaci guda kuma, ya kamata a ƙara yawan adadin yadudduka don rufin ya kai wani kauri kuma yana da yawa kuma ba ya da yawa.

03.Lalacewa

Abubuwan ciki na fenti suna amsawa tare da ƙarfe don ƙetare saman ƙarfe ko samar da abubuwa masu kariya don haɓaka tasirin kariya na rufin.Don bawuloli tare da buƙatu na musamman, dole ne ku kula da abun da ke ciki na fenti don guje wa mummunan tasiri.Bugu da ƙari, bawul ɗin ƙarfe da aka yi amfani da su a cikin bututun mai kuma na iya zama masu hana lalata ƙwayoyin cuta saboda ƙazanta samfuran da aka haifar a ƙarƙashin aikin wasu mai da aikin bushewar sabulun ƙarfe.

04. Electrochemical kariya

Lokacin da murfin dielectric shiga cikin lamba tare da karfe saman, electrochemical lalata karkashin fim zai samu.Ana amfani da ƙarfe tare da aiki mafi girma fiye da ƙarfe a matsayin masu cikawa a cikin sutura, kamar zinc.Zai taka rawar kariya a matsayin anode hadaya, kuma samfuran lalata na zinc sune zinc chloride na tushen gishiri da zinc carbonate, wanda zai cika gibin da ke cikin fim ɗin kuma ya sa fim ɗin ya takura, yana rage lalata da haɓaka rayuwar sabis. bawul.

2. Rubutun da aka fi amfani da su akan bawul ɗin ƙarfe

Hanyoyin jiyya na ƙasa na bawuloli sun haɗa da shafi fenti, galvanizing da murfin foda.Lokacin karewa na fenti gajere ne kuma ba za a iya amfani da shi a ƙarƙashin yanayin aiki na dogon lokaci ba.Ana amfani da tsarin galvanizing galibi a cikin bututun mai.Dukansu galvanizing mai zafi-tsoma da electro-galvanizing ana amfani dasu.Tsarin yana da rikitarwa.Pretreatment yana amfani da pickling da phosphating matakai.Za a sami ragowar acid da alkali a saman kayan aikin, barin lalata Hidden haɗari yana sa Layer na galvanized mai sauƙin faɗuwa.A lalata juriya na galvanized karfe ne 3 zuwa 5 shekaru.Rufin foda da aka yi amfani da shi a cikin bawul ɗin mu na Zhongfa yana da halaye na sutura mai kauri, juriya na lalata, juriya na yashwa, da dai sauransu, wanda zai iya biyan buƙatun bawuloli a ƙarƙashin yanayin amfani da tsarin ruwa.

01. Bawul jiki epoxy guduro shafi

Yana da halaye masu zuwa:

Juriya na lalata: Sandunan ƙarfe mai rufi na Epoxy suna da juriya mai kyau na lalata, kuma ƙarfin haɗin gwiwa tare da kankare yana raguwa sosai.Sun dace da yanayin masana'antu a cikin yanayi mai ɗanɗano ko kafofin watsa labarai masu lalata.

Ƙarfin mannewa: Kasancewar ƙungiyoyin polar hydroxyl da ether bond ɗin da ke cikin sarkar ƙwayar ƙwayar cuta ta epoxy resin tana sa ta manne sosai ga abubuwa daban-daban.Rashin raguwa na resin epoxy lokacin da aka warke yana da ƙananan, damuwa na ciki da aka haifar yana da ƙananan, kuma murfin kariya ba shi da sauƙi don fadowa da kasawa.

· Lantarki Properties: The warke epoxy guduro tsarin ne mai kyau insulating abu tare da high dielectric Properties, surface yayyo juriya, da baka juriya.

Tsayayyar Motsi: Tsarin resin epoxy da aka warke yana da juriya ga yawancin gyare-gyare kuma ana iya amfani dashi a cikin yanayi mai zafi.

02. Bawul farantin nailan farantin kayan

Zanen nailan yana da matuƙar juriya na lalata kuma an yi nasarar amfani da shi a aikace-aikace da yawa kamar ruwa, laka, abinci da tsaftace ruwan teku.

Ayyukan waje: Rufin farantin nailan na iya wuce gwajin feshin gishiri.Sama da shekaru 25 ba a bare shi ba bayan an nutsar da shi a cikin ruwan teku, don haka babu lalata ga sassan ƙarfe.

· Juriya na sawa: Juriya mai kyau sosai.

Tasirin juriya: Babu alamun barewa a ƙarƙashin tasiri mai ƙarfi.

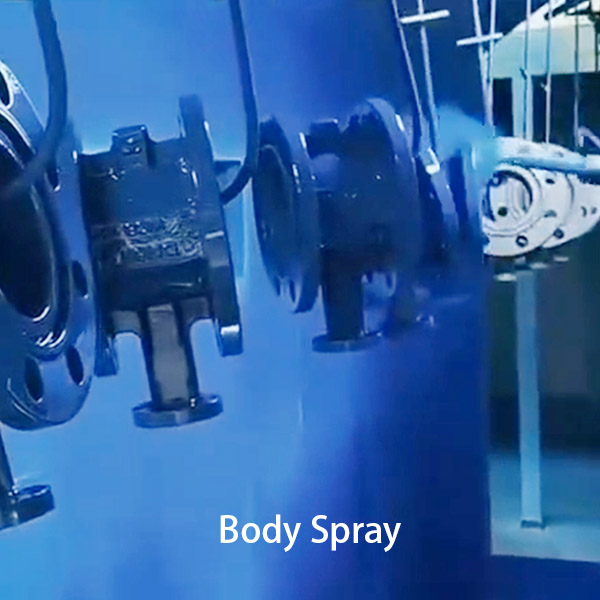

3. Tsarin fesa

A spraying tsari ne workpiece pretreatment → kura kau → preheating → spraying (primer - trimming - topcoat) → solidification → sanyaya.

Fesa fesa yafi amfani da electrostatic spraying.Dangane da girman workpiece, electrostatic spraying za a iya raba foda electrostatic spraying samar line da foda electrostatic spraying naúrar.Hanyoyin guda biyu iri ɗaya ne, kuma babban bambanci shine hanyar juyawa na workpiece.Layin samar da feshi yana amfani da sarkar watsawa don watsawa ta atomatik, yayin da aka ɗaga sashin feshin da hannu.Ana sarrafa kauri daga cikin sutura a 250-300.Idan kauri bai wuce μm 150 ba, za a rage aikin kariyar.Idan kauri ya fi 500 μm, mannewar shafi zai ragu, juriya na tasiri zai ragu, kuma amfani da foda zai karu.