A bawul mai cikakken layi na malam buɗe idoyana da cikakken tsari mai layi a cikin jikin bawul. An ƙera wannan ƙira ta musamman don aikace-aikacen da ke jure lalata.

"Cikakken layi" yana nufin cewa ba kawai diski ɗin yana rufe gaba ɗaya ba, amma kuma an rufe wurin zama gaba ɗaya, yana tabbatar da cikakken keɓewa tsakanin kafofin watsa labarai da ƙarfe.

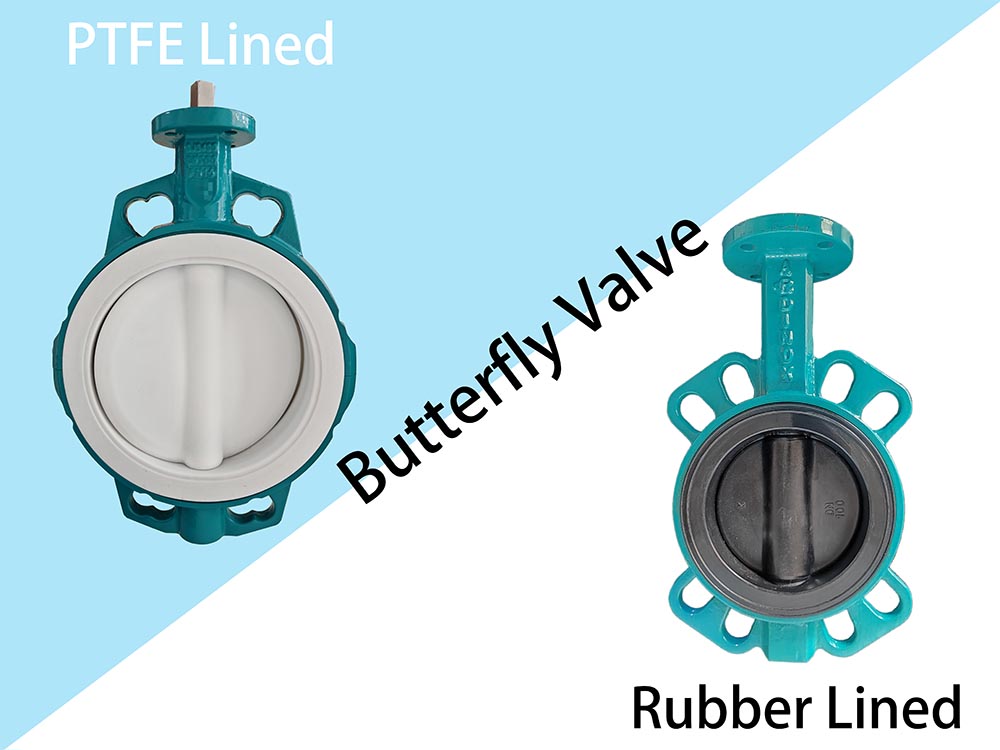

1. Abubuwa biyu na gama gari

a. PTFE (polytetrafluoroethylene, perfluoroplastic) mai rufi bawul na malam buɗe ido

b. Rubber rufin malam buɗe ido

| Nau'in Abu: | Polytetrafluoroethylene (PTFE). | Rubutun roba (misali, EPDM, Viton, NBR) |

| Tsarin Rubutu | Ana zuba Molten PTFE/PFA a cikin tsagi na dovetail akan jiki/faifai, yana samun haɗin gwiwa mara sumul. | Daga nan sai a toshe shi kai tsaye (an warkar da zafi) akan karfe, yana samar da hatimi mai mahimmanci. |

| Mahimman Features | - Kyakkyawan juriya na lalata (mai jure kusan dukkanin acid, tushe, da kaushi na kwayoyin halitta) - High zafin jiki juriya (ci gaba da aiki zazzabi har zuwa 180°C) - Low gogayya coefficient kuma maras sanda Properties, dace da high-tsarki kafofin watsa labarai

| - Kyakkyawan elasticity da kyakkyawan aikin rufewa (mai sauƙi don cimma ɗigon sifili) - Ƙananan farashi da kuma juriya mai kyau ga kafofin watsa labaru marasa lalacewa - Low zafin jiki juriya (yawanci -20°C zuwa 180°C, dangane da nau'in roba)

|

| Kafofin watsa labarai masu aiki | Acids mai ƙarfi (irin su sulfuric acid da hydrochloric acid), tushe mai ƙarfi, kaushi mai ƙarfi, ruwa mai tsafta. | ruwa, ruwan datti, raunin acid da tushe, slurries, da kafofin watsa labarai masu ingancin abinci |

| Aikace-aikace na yau da kullun | Masana'antar sinadarai (acid da canja wurin alkali), Masana'antar Pharmaceutical (canja wurin kayan tsabta mai tsabta) | Maganin Ruwa (maganin ruwan sha, ruwan famfo), HVAC Systems, Masana'antar Abinci da Abin sha, Ma'adinai (canja wurin slurry) |

2. Cikakkun matakai na Tsari don Fayafai na Valve masu layi na PTFE

2.1 Karfe Shiri

a.. Yi jifa ko injin faifan ƙarfe na ƙarfe, tabbatar da cewa saman ya kasance mai tsabta kuma ba shi da mai da gurɓatawa.

b .. Yanke tsagi (siffar dovetail) akan ainihin farfajiyar don samar da maki don allurar PTFE da hana shi faɗuwa.

2.2 PTFE Powder Molding da Preforming

a. Sanya adadin PTFE foda (ko premix) da aka ƙididdige a hankali a cikin ƙirar, saka babban bawul ɗin ƙarfe na malam buɗe ido, sannan ƙara PTFE foda.

b. A hankali a yi amfani da injin motsa jiki (share) da matsa lamba (matsi ko latsawa) don samar da tayin kore. Isostatic gyare-gyaren: nutsar da mold a cikin ruwa kuma yi amfani da matsa lamba iri ɗaya a kowane bangare (gudanar ruwa na ruwa) don tabbatar da tsari da tsari mai yawa (porosity as low as <1%).

2.3 Ciwon kai da Ciwon kai

a. Sanya koren amfrayo a cikin tanda da siter a 380 ° C na tsawon sa'o'i 5-24 (a hankali ƙara yawan zafin jiki don kauce wa tsagewa).

b. Sannu a hankali zuwa zafin jiki don ba da damar PTFE don crystallize da fuse tare da ginshiƙi na ƙarfe, yana samar da suturar da ba ta da kyau (ana sarrafa kauri don zama 3-10mm, daidaitawa bisa ga yanayin yanayi).

2.4 Injiniya da Ƙarshe:

Yi amfani da injin lathe ko na'urar CNC don injin diamita na ciki da na waje don tabbatar da fayafai da wurin zama sun dace daidai (haƙuri suna da ƙarfi, misali, ± 0.01mm).

2.5 Ingancin Bincike da Gwaji:

a. Ma'aunin Kauri: Tabbatar da ƙaramin rufi na 3mm, ko kuma kamar yadda aka keɓance shi.

b. Gwajin Spark: 35,000 volts don gwaji mai ƙarfi (babu raguwa da ke nuna karɓa).

c. Gwajin Vacuum/Ƙarfi: Yana daidaita yanayin aiki don bincika leaks da haɓaka (daidai da EN 12266-1 ko API 598).

d. Gwajin Haɓakawa (na zaɓi): Juriya na saman <10⁶Ω don aikace-aikacen tabbatar da fashewa.

3. Cikakken Matakan Tsari don Fayafai masu layi na EPDM

3.1 Karfe Shiri

a. Yi jifa ko injin ginshiƙin ƙarfe don tabbatar da tsaftataccen wuri mara tsatsa.

b. Yashi ko sinadarai etch saman (roughness Ra 3-6μm) don haɓaka mannewar EPDM.

3.2 EPDM Compound Application da Preforming

Ana sanya fili na EPDM mara magani (sheet ko ruwa) a cikin wani gyaggyarawa, ana nannade kewayen tsakiyar ƙarfe. Yin amfani da gyare-gyaren matsawa ko zubawa, a ko'ina rarraba fili a saman fayafai na bawul don samar da jiki mai kore. Kula da kauri na 2-5 mm, tabbatar da ɗaukar hoto a kusa da gefuna na diski.

3.3 Ciwon kai

Ana sanya jikin kore a cikin autoclave kuma mai zafi tare da tururi ko iska mai zafi (150-180 ° C, matsa lamba> 700 psi, don 1-4 hours).

Tsarin warkarwa ya haye kuma yana warkar da EPDM, ta hanyar sinadarai da injina yana haɗa shi zuwa tsakiyar ƙarfe don samar da lullubi, rufin yanki ɗaya. Ƙara yawan zafin jiki a hankali don guje wa kumfa na iska ko fasa.

3.4 Ƙarshen Mashin ɗin

Bayan sanyaya, a datse gefuna na ciki da na waje ta amfani da latalin CNC don tabbatar da fayafai da wurin zama sun dace daidai (haƙuri ± 0.05 mm). Cire roba mai wuce gona da iri kuma duba bayanin martabar gefen (rufin Ni-Cu zaɓi ne don ingantaccen juriya).

3.5 Ingancin Bincike da Gwaji

a. Gwajin kauri da Adhesion: Ma'aunin kauri na Ultrasonic (mafi ƙarancin 2mm); Gwajin tensile (ƙarfin kwasfa> 10 N/cm).

b. Tabbatar da Aiki: Gwajin Hatimin Bubble Tight (ma'aunin API 598); Gwajin matsin lamba / Vacuum (PN10-16, juriya mara kyau).

c. Gwajin Chemical / Tsufa: Yin nutsewa a cikin kafofin watsa labarai na acid da alkaline, haɓaka haɓaka <5%; Yawan zafin jiki (120 ° C, 72h).

4. Jagorar Zaɓi

Rubutun PTFE sun dace da kafofin watsa labarai masu lalata sosai (kamar acid, alkalis, da kaushi), yayin da rufin EPDM ya dace da tushen ruwa, kafofin watsa labarai masu laushi (kamar ruwa da acid dilute). Ba da fifikon dacewa da sinadarai, zafin jiki, matsa lamba, da farashi don inganta aikace-aikacen. Zhongfa Valve yana kera cikakkun bawul ɗin malam buɗe ido tare da zaɓin walƙiya, flange, da zaɓin lugga. Da fatan za a tuntuɓe mu da kowace tambaya.

Lokacin aikawa: Oktoba-28-2025