Bawuloli na malam buɗe idosune nau'in bawul ɗin malam buɗe ido da aka fi amfani dashi a cikin bututun masana'antu. Suna amfani da kayan roba kamar roba a matsayin saman rufewa, suna dogaro da "jurewar kayan aiki" da "matsin tsari" don cimma aikin rufewa.

Wannan labarin ba kawai ya gabatar da tsari, amfani, da kayan aiki ba, har ma yana nazarin su daga ilimin gabaɗaya zuwa zurfin tunani.

1. Asalin Fahimtar Bawul ɗin Butterfly Resilient (Taƙaitaccen Bayani)

1.1 Babban Tsarin

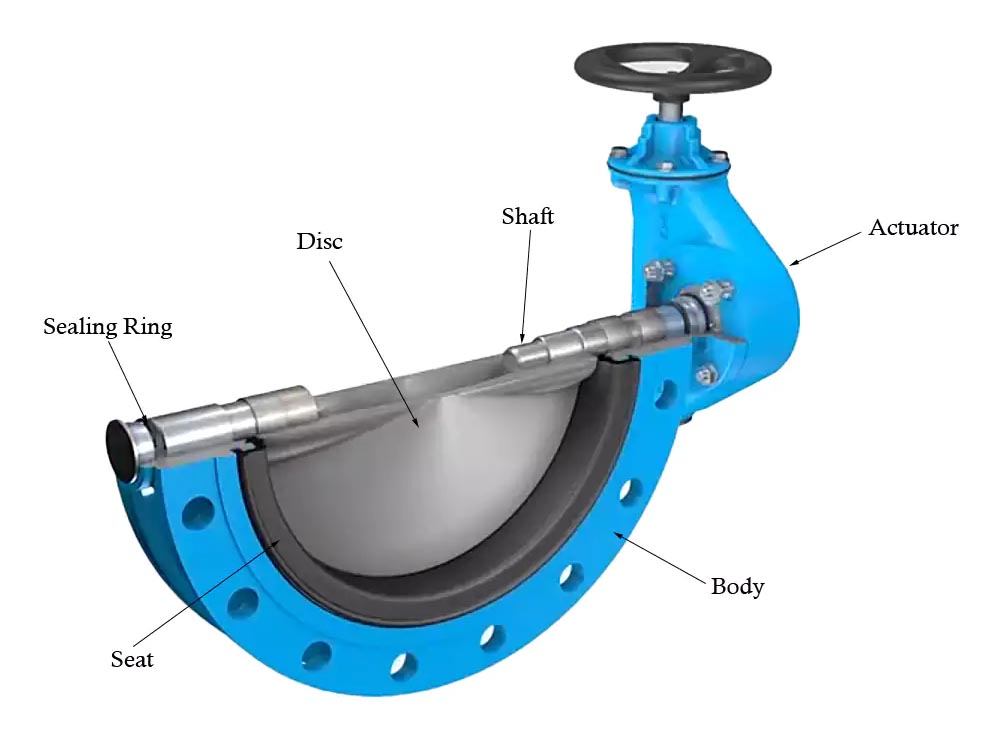

Bawul Jikin:Yawanci nau'in wafer, nau'in lugga, ko nau'in flanged.

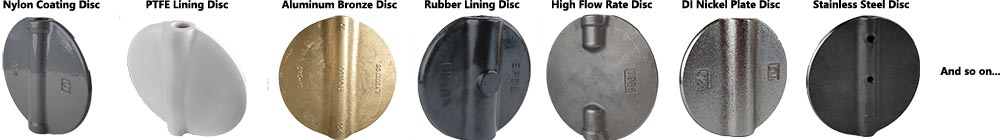

Valve Disc:Farantin karfe madauwari wanda ke damfara kujerar roba lokacin da aka rufe don ƙirƙirar hatimi.

Wurin Wuta:An yi shi da kayan roba kamar NBR/EPDM/PTFE/Rubber Lined, yana aiki tare da diski na bawul.

Bawul Stem:Mafi yawa suna amfani da sigar-shaft ko ƙirar shaftaya.

Mai kunnawa:Handle, tsutsa kayan aiki, lantarki, pneumatic, da dai sauransu.

1.2 Abubuwan gama gari

Matsakaicin hatimi yawanci yana kaiwa ga zubewar sifili.

Low cost da fadi da kewayon aikace-aikace.

Mafi yawa ana amfani dashi a cikin ƙananan tsarin matsa lamba kamar ruwa, kwandishan, HVAC, da masana'antar sinadarai masu haske.

2. Rashin fahimta game da Resilient Butterfly Valves

2.1 Asalin rufewa shine juriyar roba

Mutane da yawa sun gaskata: "Kujeru masu juriya sun dogara da juriyar roba don rufewa."

Hakikanin hatimi shine:

Bawul Jikin + bawul tushe nesa + bawul diski kauri + bawul kujera saka hanya

Tare ƙirƙirar "yankin matsawa mai sarrafawa".

A sauƙaƙe:

Robar ba zai iya zama sako-sako da yawa ko matsewa ba; ya dogara da "yankin matsawa" wanda aka sarrafa ta hanyar yin daidaitattun kayan aiki.

Me yasa wannan yake da mahimmanci?

Rashin isassun matsi: Valve yana zubowa idan an rufe.

Matsawa mai wuce gona da iri: Matsananciyar ƙarfi mai ƙarfi, tsufa na roba.

2.2 Shin siffar diski mafi sauƙi ta fi ƙarfin kuzari?

Ra'ayi gama gari: Fayafai masu ɗorewa na bawul na iya rage asarar matsa lamba.

Wannan gaskiya ne bisa ka'idar "masu aikin injiniya", amma bai dace da ainihin aikace-aikacen Resilient Butterfly Valves ba.

Dalili:

Babban tushen asarar matsin lamba a cikin bawul ɗin malam buɗe ido ba siffar faifan bawul ba ne, amma “tasirin ramin tashar micro-tashar” wanda ya haifar da ƙanƙantar robar kujerar bawul. Fayil ɗin bawul ɗin da yake sirara yayi yawa zai iya kasa samar da isassun matsi na lamba, mai yuwuwar haifar da katsewar layukan rufewa da zubewa.

Fayil ɗin bawul ɗin da aka daidaita zai iya haifar da matsanancin damuwa akan roba, yana rage tsawon rayuwarsa.

Sabili da haka, ƙirar bawul ɗin malam buɗe ido mai laushi yana ba da fifikon "kwanciyar hankali" akan daidaitawa.

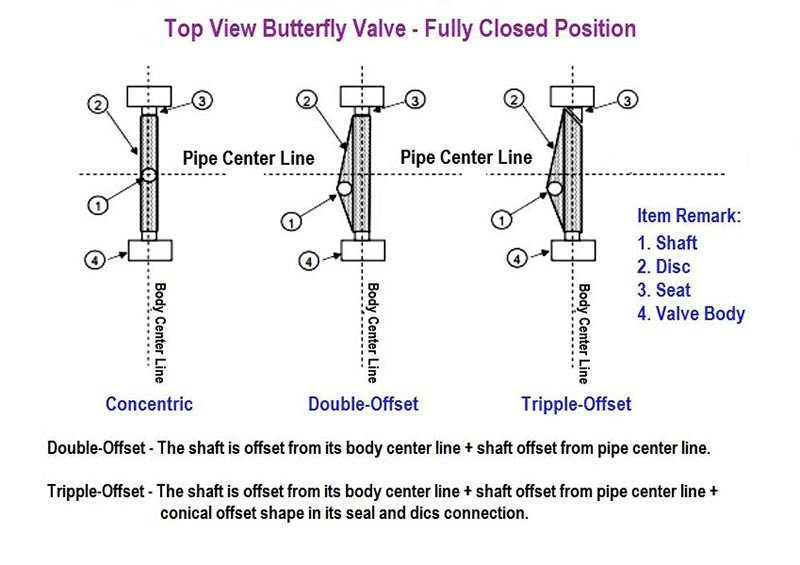

2.3 Bawul ɗin malam buɗe ido masu laushi kawai suna da tsarin tsakiya

Yawancin lokaci ana faɗa akan layi cewa bawul ɗin malam buɗe ido ya kamata su yi amfani da hatimin ƙarfe.

Koyaya, ƙwarewar injiniya ta zahiri ta nuna cewa:

Sau biyu eccentricity yana inganta rayuwar Resilient Butterfly Valves sosai.

Dalili:

Sau biyu eccentricity: Bawul faifan kawai yana tuntuɓar robar a lokacin 2-3° na ƙarshe na rufewa, yana rage juzu'i.

Ƙananan juzu'i, yana haifar da ƙarin zaɓin actuator na tattalin arziki.

2.4 Babban abin la'akari don kujerar roba shine "sunan abu"*

Yawancin masu amfani suna mayar da hankali kan:

EPDM

NBR

Viton (FKM)

Amma abin da ya shafi rayuwar gaske shine:

2.4.1 Taurin bakin teku:

Misali, Shore A hardness na EPDM ba lamari bane na "mafi laushin kyau." Yawancin lokaci, 65-75 shine mafi kyawun ma'aunin ma'auni, samun ɗigon sifili a ƙananan matsa lamba (PN10-16).

Taushi mai laushi: Ƙarƙashin juzu'i amma cikin sauƙin tsagewa. A cikin kololuwar matsa lamba (> 2 MPa) ko mahalli masu tashe-tashen hankula, roba mai laushi yana matsawa sosai, yana haifar da nakasar extrusion. Bugu da ƙari, yawan zafin jiki (> 80 ° C) yana ƙara yin laushi da roba.

Da wuya: Yana da wuyar hatimi, musamman ma a cikin tsarin ƙananan matsa lamba (<1 MPa), inda ba za a iya matse robar ba sosai don samar da haɗin iska, wanda ke haifar da ƙananan leakage.

2.4.2 Vulcanization zafin jiki da lokacin warkewa

Zazzabi na Vulcanization da lokacin warkewa suna sarrafa haɗin giciye na sarƙoƙi na ƙwayoyin roba, kai tsaye yana shafar kwanciyar hankali na tsarin cibiyar sadarwa da aiki na dogon lokaci. Matsakaicin iyaka shine 140-160 ° C, mintuna 30-60. Maɗaukakin zafi ko ƙarancin zafi yana haifar da rashin daidaituwar magani da saurin tsufa. Kamfaninmu gabaɗaya yana amfani da vulcanization mataki-mataki (pre-curing a 140 ° C, sannan bayan-curing a 150 ° C). 2.4.3 Saitin Matsi

Saitin matsawa yana nufin adadin nakasu na dindindin wanda roba ke fama da shi a ƙarƙashin damuwa akai-akai (yawanci 25% -50% matsawa, an gwada shi a 70°C/22h, ASTM D395) kuma ba zai iya warkewa gabaɗaya ba. Madaidaicin ƙimar saitin matsawa shine <20%. Wannan darajar ita ce "kwalin kwalba" don dogon lokaci na hatimi na bawul; dogon lokaci high matsa lamba yana kaiwa ga m gibba, forming yayyo maki.

2.4.4 Ƙarfin Ƙarfi

A. Ƙarfin Ƙarfin Ƙarfin Ƙarfi (yawanci> 10 MPa, ASTM D412) shine matsakaicin matsananciyar damuwa da roba zai iya jurewa kafin karaya, kuma yana da mahimmanci ga juriya na lalacewa da juriya na wurin zama. Abubuwan da ke cikin roba da rabon baƙar fata na carbon suna ƙayyade ƙarfin juzu'i na kujerar bawul.

A cikin bawuloli na malam buɗe ido, yana tsayayya da shear ta gefen faifan bawul da tasirin ruwa.

2.4.5 Babban ɓoyayyen ɓoyayyen ɓoyayyen bawul ɗin malam buɗe ido shine zubewa.

A cikin hatsarori na injiniya, ɗigon ruwa sau da yawa ba shine babbar matsala ba, sai dai karuwar karfin wuta.

Abin da ke haifar da gazawar tsarin shine:

Zazzagewar kwatsam → lalacewar gear tsutsa → tayar da mai kunnawa → cushewar bawul

Me yasa karfin juyi ya karu ba zato ba tsammani?

- High-zazzabi fadada wurin bawul

- Shayewar ruwa da fadada roba (musamman EPDM mara inganci)

- Nakasar roba ta dindindin saboda matsawa na dogon lokaci

- Tsarin da ba daidai ba na rata tsakanin ƙwanƙwasa bawul da diski bawul

- Bawul kujera bai karye daidai ba bayan maye gurbin

Saboda haka, "ƙarfin juzu'i" alama ce mai mahimmanci.

2.4.6 Daidaitaccen injin injin bawul ba shi da mahimmanci.

Mutane da yawa sun yi kuskuren yin imani cewa hatimin bawul ɗin malam buɗe ido mai laushi ya dogara ne akan roba, don haka daidaitattun kayan aikin injin ba su da girma.

Wannan ba daidai ba ne.

Daidaiton jikin bawul yana rinjayar:

Zurfin wurin zama na Valve → rufewa da karkatar da matsi, cikin sauƙin haifar da rashin daidaituwa yayin buɗewa da rufewa.

Rashin isasshen chamfering gefen tsagi → zazzagewa yayin shigar da kujerar bawul

Kuskure a tsakiyar nisa na faifan bawul → mahaɗar lamba fiye da kima

2.4.7 Mahimmancin "cikakkiyar roba/PTFE masu layi na malam buɗe ido" shine faifan bawul.

Jigon cikakken tsarin roba ko PTFE mai layi ba shine "a sami yanki mafi girma wanda ke bayyana juriya ba," amma don toshe matsakaici daga shigar da ƙananan tashoshi a cikin jikin bawul. Matsaloli da yawa tare da bawul ɗin malam buɗe ido marasa tsada ba saboda ƙarancin ingancin roba ba ne, amma a maimakon haka:

“Ratar mai siffa mai siffa” a mahadar kujerar bawul da jiki ba a magance shi da kyau ba.

Yashwar ruwa na dogon lokaci → microcracks → kumburin roba da kumburi

Mataki na ƙarshe shine gazawar wurin zama na bawul.

3. Me yasa ake amfani da Resilient Butterfly Valves a duk duniya?

Bayan ƙananan kuɗi, dalilai uku masu zurfi sune:

3.1. Hakuri mai girman gaske

Idan aka kwatanta da hatimin ƙarfe, hatimin roba, saboda kyakkyawan ƙarfin su, suna da ƙarfin juriya don rarrabuwa na shigarwa da ƙananan nakasawa.

Ko da kurakurai prefabrication bututu, flange sabawa, da m aron kusa danniya suna tunawa da elasticity na roba (ba shakka, wannan yana da iyaka da wanda ba a so, kuma zai haifar da wasu lalacewa ga bututun da bawul a cikin dogon gudu).

3.2. Mafi kyawun daidaitawa ga jujjuyawar matsin lamba

Rumbun hatimin ba su da “karguje” kamar hatimin ƙarfe; suna rama layin rufewa ta atomatik yayin hawan matsin lamba.

3.3. Mafi ƙasƙanci jimlar farashin sake zagayowar rayuwa

Bawul ɗin malam buɗe ido masu wuya sun fi ɗorewa, amma farashi da farashin mai kunnawa sun fi girma.

A kwatankwacin, jimlar saka hannun jari da kula da Resilient Butterfly Valves sun fi tattalin arziki.

4. Kammalawa

DarajarBawul ɗin Butterfly Resilientba kawai "launi mai laushi ba"

Bawul ɗin malam buɗe ido mai laushi na iya zama mai sauƙi, amma samfuran gaske suna da goyan bayan ingantaccen dabaru na injiniyoyi, gami da:

Madaidaicin ƙirar yankin matsawa

Ayyukan roba mai sarrafawa

Geometric matching na bawul jiki da kara

Valve wurin taro tsari

Gudanar da Torque

Gwajin zagayowar rayuwa

Waɗannan su ne mahimman abubuwan da ke ƙayyade inganci, ba "sunan abu" da "tsarin bayyanar ba".

NOTE:* DATA tana nufin wannan gidan yanar gizon:https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Lokacin aikawa: Dec-09-2025