Bawul ɗin malam buɗe ido yana yin gwaje-gwaje da yawa tun daga masana'anta har zuwa jigilar kaya don tabbatar da inganci da amincinsa. Cikakken binciken ya ƙunshi abubuwa na yau da kullun kamar kayan aiki, shafi, kamanni, roba, matsi, da girma, da kuma aikin rufewa, kamanni, ƙarfin juyi, tauri, kauri, haɗakarwa, daidaiton zare da flange, da kuma alamun gano abubuwa.

Ana iya gudanar da tsarin dubawa kamar haka: Duba kayan da aka sarrafa → Duba aikin samfuri → Gwajin aikin da aka gama → Karɓar ƙarshe. Kowane fanni an yi bayani ne tare da takamaiman hanyoyi da ƙa'idodi.

Tsarin Duba Bawul ɗin Malam Buɗe Ido

1. Duba Kayan Danye

1.1 Manufa

Don tabbatar da cewa kayan aiki kamar jikin bawul, farantin bawul, sandar bawul, da zoben rufewa sun cika buƙatun da aka saba.

1.2 Abubuwan Dubawa:

- Binciken Sinadaran Sinadarai: Ta amfani da na'urar auna sigina ko hanyar nazarin sinadarai, tabbatar da takardar shaidar kayan don tabbatar da bin ƙa'idodin kayan ASTM/GB/EN.

- Gwajin Aikin Inji: Ana yin samfurin gwaji don gwajin juriya, yawan amfanin ƙasa, tsawaitawa, da kuma gwajin tasiri.

- Gano Kayan Aiki da Bin Diddiginsu: Dole ne a gano kowane rukuni na kayan aiki ta lambar murhu don tabbatar da gano asalinsu.

- Dubawa ta hanyar ƙarfe (Zaɓi): Duba simintin don ganin lahani kamar su tarkacen da ke cikin tarkacen da kuma ramuka.

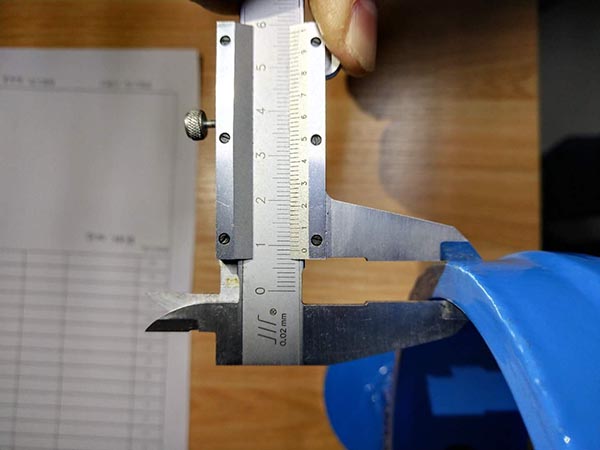

2. Duba Girma

Kayan aiki: Ma'aunin Vernier, ma'aunin diamita na ciki, ma'aunin zurfin.

2.1 Manufa

Don tabbatar da cewa girman samfurin ya dace da zane-zane na yau da kullun don sauƙin shigarwa da musanya.

2.2 Abubuwan Dubawa

Tsawon jikin bawul (girman fuska da fuska)

Tazarar ramin haɗin flange, diamita na rami, ƙayyadaddun zaren

Kauri farantin bawul da kuma izinin gefen

Zurfin zaren da haƙuri

3. Duba Roba da Kujeru

Kayan Aiki Na Yau Da Kullum: EPDM, NBR, VITON, PTFE.

3.1 Manufa

Don tabbatar da juriyar matsin lamba, juriyar zafin jiki, da juriyar tsatsa na kayan rufewa.

3.2 Abubuwan Dubawa

Tabbatar da Kayan Aiki

A duba santsi a saman, babu burrs, kumfa, da datti.

Duba ma'aunin maɓallan zoben rufewa, kamar diamita mai sassauƙa da diamita na ciki da na waje.

Taurin roba (mai gwajin taurin bakin teku), saitin matsi, ƙarfin taurin kai, da sauransu.

Gwajin juriyar ƙaiƙayi

Daidaiton farantin bawul da kuma daidaito

4. Duba Rufi

4.1 Manufa

Domin tabbatar da juriyar tsatsa, mannewa, da kauri na shafi sun cika ka'idodi.

4.2 Abubuwan Dubawa

Tsarin gyaran saman (cire tsatsa) kafin fesawa (Sa2.5 ko sama da haka, babu sikelin da ake gani ko tsatsa)

Kauri bayan fesawa (ta amfani da ma'aunin kauri na shafi)

Mannewa na shafi (gwajin yanke-yanke, tazara ta 1mm, yankin cirewar shafi ≤5% bayan cire tef)

Dubawa (sags, ramukan filaye, kumfa, bawon lemu, bambancin launi)

Gwajin fesa gishiri da juriya ga lalatawa

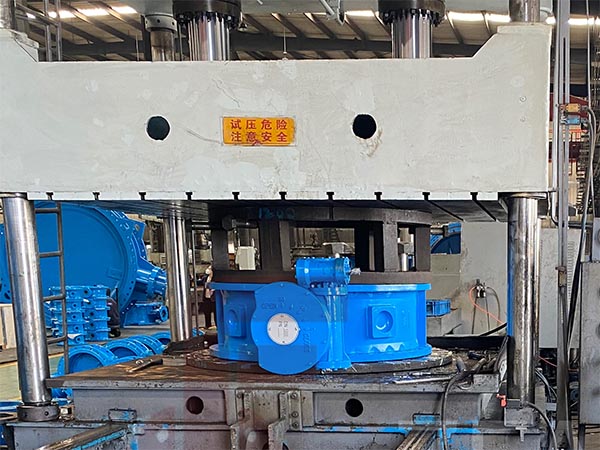

5. Gwajin Matsi da Zubewa

5.1 Manufa

Don tabbatar da cewa bawul ɗin ba ya zubewa a ƙarƙashin matsin lamba mai ƙima.

5.2 Ka'idojin Karɓa

Ba dole ba ne jikin bawul ɗin da duk abubuwan da ke ɗauke da matsi su kasance suna da wata lalacewa ta tsarin, nakasa ta dindindin, ko kuma zubewa.

5.3 Abubuwan Gwaji

Gwajin Ƙarfin Shell: Gwajin Hydrostatic a matsin lamba sau 1.5, lokacin riƙewa ≥ mintuna 2.

Gwajin Hatimi: Gwajin Hatimi na gaba da na baya sau 1.1 a matsi mai ƙima.

Gwajin Tsaftace Iska: Gano ƙananan zubar ruwa ta amfani da iska ko nitrogen a 0.6 MPa.

Ma'aunin Zubar da Ruwa: Ya cika buƙatun API 598 / ISO 5208.

6. Gwajin Juyin Juya Halin Aiki

6.1 Manufa

Don tabbatar da ko ƙarfin buɗewa da rufewa ya cika ƙa'idar kuma yana cikin buƙatun ƙira, tabbatar da cewa na'urar tuƙi ta dace.

Hanyar Gwaji

Ana aunawa ta amfani da maƙullan ƙarfin juyi da mitar ƙarfin juyi kamar na'urorin kunna wutar lantarki; kwatanta ƙarfin juyi da ƙarfin juyi da aka auna.

7. Duba Gani & Alamar

7.1 Manufa

Don tabbatar da ingancin bayyanar da kuma takamaiman alamun.

7.2 Abubuwan Gwaji

Babu wani ƙarfe, tarkacen walda, tabon mai, ko wasu ƙazanta a ciki.

Babu tsagewa, ƙuraje, ko tsatsa. Santsi a saman da kuma daidaiton launi. Bayanin lakabin suna (samfuri, ƙimar matsi, kayan aiki, kibiyar alkiblar kwarara) a bayyane yake, cikakke ne, kuma amintacce.

8. Gwajin Aiki

8.1 Manufa

Don tabbatar da inganci da aikin kwararar bawul ɗin.

8.2 Abubuwan Gwaji

Sassaucin buɗewa da rufewa na farantin bawul

Daidaiton matsayi na bawul

Ma'aunin ma'aunin juriyar kwarara (ƙimar Cv)

Daidaiton alkiblar kwararar ruwa

9. Dubawa na Ƙarshe da Duba Masana'antu

9.1 Manufa

Domin a tantance ko samfurin ya cancanta kuma a shirye yake don jigilar kaya.

9.2 Ya haɗa

Bitar bayanan gwaji

Manne takardar shaidar daidaito da lakabin gwaji

Ko marufin yana kare shi daga lalacewa yayin jigilar kaya, da kuma ko akwai murfi masu kariya a fuskar flange da ƙarshen zare.

Lokacin Saƙo: Oktoba-28-2025