Lug Type Butterfly bawul da Jiki

Cikakken Bayani game da Samfurin

| Girman da Matsi da Matsayin Daidaitacce | |

| Girman | DN40-DN1600 |

| Matsayin Matsi | PN10, PN16, CL150, JIS 5K, JIS 10K |

| STD fuska da fuska | API609, BS5155, DIN3202, ISO5752 |

| Haɗin STD | PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| Babban Flange STD | ISO 5211 |

| Kayan Aiki | |

| Jiki | Baƙin ƙarfe (GG25), ƙarfe mai ƙarfi (GGG40/50), ƙarfe mai ƙarfi (WCB A216), ƙarfe mai ƙarfi (SS304/SS316/SS304L/SS316L), ƙarfe mai ƙarfi mai ƙarfi mai ƙarfi (2507/1.4529), tagulla, ƙarfe mai ƙarfi na aluminum. |

| Faifan diski | DI+Ni, Carbon Karfe (WCB A216), Bakin Karfe (SS304/SS316/SS304L/SS316L), Bakin Karfe Duplex (2507/1.4529), Tagulla, DI/WCB/SS mai rufi da fenti na Epoxy/Nylon/EPDM/NBR/PTFE/PFA |

| Tushe/Shaft | SS416, SS431, SS304, SS316, Bakin Karfe Duplex, Monel |

| Kujera | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

| Bushing | PTFE, Tagulla |

| Zoben O | NBR, EPDM, FKM |

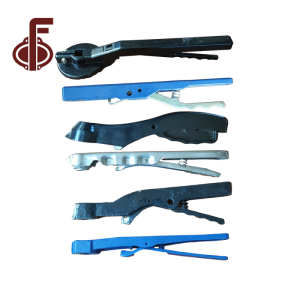

| Mai kunnawa | Lever na hannu, Akwatin Gear, Mai kunna wutar lantarki, Mai kunna iska |

Nunin Samfura

Amfanin Samfuri

Bawul ɗin malam buɗe ido na gabaɗaya wanda aka ƙera bisa ga EN 593. Akwai kayan aiki iri-iri da ake amfani da su don aikace-aikace daban-daban.

Tsarin wurin zama na harshe da tsagi yana kulle wurin zama kuma yana ba da damar bawul ɗin malam buɗe ido.

Ana gwada bawulan ZFA a matsin lamba 110% don tabbatar da cewa ba a rufe kumfa ba.

Bawuloli na malam buɗe ido na ZFA ƙira ce mara pinless.

Sinadaran sinadarai, yanayi, gogewa da kuma shafa mai jure wa tasiri.

Faifan bawul ɗin malam buɗe ido mai lanƙwasa yana da bearings masu hanyoyi biyu, kyakkyawan hatimi kuma babu ɓuya yayin gwajin matsin lamba.

Lanƙwasa mai gudana yakan kasance madaidaiciya. Kyakkyawan aikin daidaitawa.

Tsarin farantin tsakiya, ƙaramin ƙarfin buɗewa da rufewa

Dogon lif mai aiki. Jure gwajin dubban ayyukan buɗewa da rufewa.

Gwajin wurin zama: ruwa sau 1.1 a matsin lamba na aiki.

Gwajin Aiki/Aiki: A lokacin dubawa na ƙarshe, kowace bawul da mai kunna ta (lever/gear/pneumatic actuator) za su yi gwajin aiki gaba ɗaya (buɗe/rufe). Ana yin gwajin ba tare da matsi ba kuma a yanayin zafi na yanayi. Yana tabbatar da aiki yadda ya kamata na haɗa bawul/actuator, gami da kayan haɗi kamar bawul ɗin solenoid, maɓallan iyaka, masu daidaita matatun iska, da sauransu.

Ana amfani da bawul ɗin lug ne galibi don kwararar bututun mai, matsi da kuma sarrafa zafin jiki a cikin masana'antu daban-daban na sarrafa kansa, kamar: wutar lantarki, sinadarai na petrochemical, ƙarfe, kariyar muhalli, sarrafa makamashi, tsarin kariyar wuta da kuma tallace-tallace na bawul ɗin malam buɗe ido.

A lokaci guda, bawul ɗin lug yana da kyakkyawan aikin sarrafa ruwa kuma yana da sauƙin aiki.

Ba wai kawai ana amfani da su sosai a masana'antu kamar man fetur, iskar gas, sinadarai, maganin ruwa, da sauransu ba, har ma a tsarin sanyaya ruwan tashoshin samar da wutar lantarki ta zafi.