A bangaren sarrafa ruwa na masana'antu,malam buɗe idotaka muhimmiyar rawa wajen daidaitawa, jagora, da ware kwararar ruwa, iskar gas, da slurries a cikin bututun mai. Bawul ɗin malam buɗe ido nau'in nau'in haɗin gwiwa ne guda ɗaya, wanda ke nuna flanges na haɗin kai a ƙarshen jikin bawul ɗin, yana ba da damar amintattun haɗin haɗin gwiwa zuwa flanges na bututu.

Tsarin juyi-kwata na aflanged malam buɗe ido bawulyana bambanta shi da bawul ɗin layi kamar ƙofar kofa ko globe valves, yana ba da fa'idodi cikin saurin gudu da ingantaccen sarari.

Wannan labarin zai shiga cikin cikakkun bayanai na bawul ɗin malam buɗe ido, wanda ke rufe ƙirar su, nau'ikan, kayan aiki, aikace-aikace, fa'idodi da rashin amfani, shigarwa, kiyayewa, kwatancen sauran bawuloli, da yanayin gaba.

1. Ma'anar da Ƙa'idar Aiki

Bawul ɗin malam buɗe ido shine bawul ɗin juyawa na digiri 90 wanda ke ɗauke da faifai wanda ke sarrafa kwararar ruwa ta hanyar jujjuyawar tushe. Jikin bawul ɗin yana fasalin flanges akan iyakar biyu don haɗin haɗin kai tsaye zuwa bututun. Flange bawul ɗin malam buɗe ido suna da haɓaka ko lebur flanges tare da ramukan kulle, samar da ingantacciyar haɗin gwiwa da kwanciyar hankali wanda ya dace da ƙananan, matsakaita, da aikace-aikacen matsa lamba, da ƙanana, matsakaici, da manyan diamita.

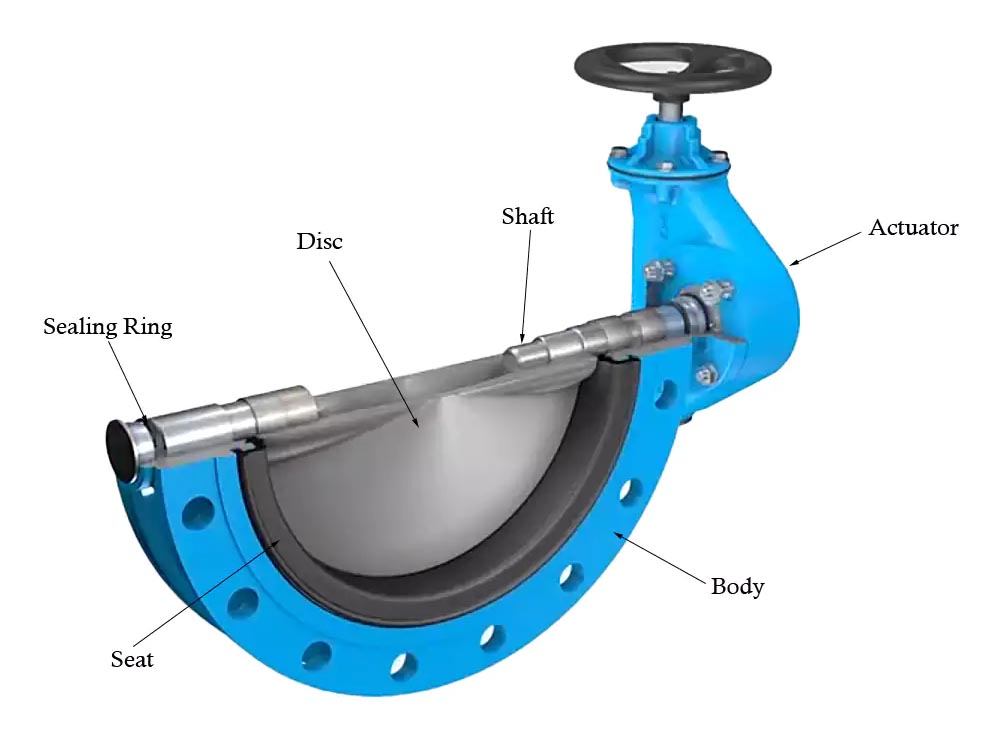

Ka'idar aiki mai sauƙi ne kuma mai tasiri. Bawul ɗin ya ƙunshi jikin bawul, faifan bawul, madaurin bawul, wurin zama, da mai kunnawa. Lokacin da aka yi amfani da hannu ko kayan aiki, ko maɓallin bawul ɗin yana jujjuya ta atomatik mai kunnawa, faifan bawul ɗin yana juyawa daga matsayi daidai da hanyar kwarara (cikakken buɗe) zuwa matsayi mai tsayi (cikakken rufe). A cikin buɗaɗɗen wuri, diski ɗin bawul yana daidaitawa tare da bututun bututun, rage girman juriya da asarar matsa lamba. Lokacin da aka rufe, faifan bawul yana hatimi akan wurin zama a cikin jikin bawul.

Wannan tsarin yana ba da damar yin aikin bawul mai sauri, yawanci yana buƙatar jujjuyawar digiri 90 kawai, yana mai da shi sauri fiye da bawuloli masu juyawa da yawa. Bawul ɗin malam buɗe ido na iya ɗaukar kwararar bidirectional kuma galibi ana sanye su da kujerun juriya ko kujerun ƙarfe don tabbatar da rufewar. Tsarin su ya sa su dace musamman don tsarin da ke buƙatar sauyawa akai-akai ko kuma inda sarari ya iyakance.

2. Abubuwa

Manyan abubuwa sun haɗa da:

- Bawul Jikin: Gidajen waje, yawanci gine-gine mai nau'i biyu, yana ba da haɗin gine-gine kuma yana gina abubuwan ciki. Ana amfani da ƙarfe na carbon don amfanin gabaɗaya, bakin karfe don juriya na lalata, tagulla na nickel-aluminum don mahallin marine, da gami da ƙarfe don matsanancin yanayi.

- Valve Disc:Abun jujjuyawar, wanda ake samu a cikin ko dai tsararru ko ƙira, yana sarrafa kwararar. Faifan na iya zama a tsakiya ko a kashe shi don haɓaka aiki. Bakin karfe, tagulla na aluminium, ko mai rufi da nailan don ingantacciyar juriyar lalacewa.

- kara: Shaft ɗin da ke haɗa diski ɗin bawul zuwa mai kunnawa yana watsa ƙarfin juyawa. Bakin karfe ko maɗaukaki masu ƙarfi suna jure juriya.

Ana amfani da mai tushe ta hanyar-shaft ko guda biyu, sanye take da hatimi don hana zubewa.

- Zama: An yi farfajiyar rufewa da kayan elastomeric kamar EPDM ko PTFE. EPDM (-20°F zuwa 250°F), BUNA-N (0°F zuwa 200°F), Viton (-10°F zuwa 400°F), ko PTFE (-100°F zuwa 450°F) ana amfani dashi don hatimi mai laushi; Ana amfani da kayan ƙarfe kamar bakin karfe ko Inconel don hatimi mai zafi mai zafi.

- Mai kunnawa: Ana aiki da hannu (hannu, gear) ko mai ƙarfi (na huhu, lantarki).

- Shirya da gaskets: Tabbatar da hatimai masu tsattsauran ra'ayi tsakanin abubuwan haɗin gwiwa da haɗin haɗin flange.

Waɗannan abubuwan haɗin gwiwa suna aiki tare don samar da ingantaccen sarrafa kwarara.

3. Nau'in Flanged Butterfly Valves

Za a iya rarraba bawul ɗin malam buɗe ido kamar haka dangane da daidaita diski, hanyar kunnawa, da nau'in jiki.

3.1 Daidaitawa

- Concentric (sifili diyya): Ƙaƙƙarfan bawul ɗin ya shimfiɗa ta tsakiyar diski kuma yana nuna wurin zama mai jurewa. Wannan bawul ɗin ya dace da aikace-aikacen ƙananan matsa lamba tare da yanayin zafi har zuwa 250°F.

- Biyu biya diyya: Bawul mai tushe an kashe shi a bayan diski da kashe-tsakiya, yana rage lalacewa. Wannan bawul ɗin ya dace da aikace-aikacen matsakaici-matsi da yanayin zafi har zuwa 400°F.

- Sau uku biya diyya: Ƙaƙƙarfan kusurwar wurin zama mai ɗorewa yana haifar da hatimin ƙarfe-zuwa-ƙarfe. Wannan bawul ɗin ya dace da matsa lamba mai ƙarfi (har zuwa Class 600) da zafi mai zafi (har zuwa 1200).°F) aikace-aikace kuma ya cika buƙatun sifili.

3.2 Hanyar Aiki

Nau'in kunnawa sun haɗa da manual, pneumatic, lantarki, da na'ura mai aiki da karfin ruwa don ɗaukar buƙatun aiki iri-iri.

4. Aikace-aikacen masana'antu

Flanged malam buɗe ido ana amfani da ko'ina a cikin wadannan sassa:

- Maganin Ruwa da Ruwa: Ana amfani da shi don daidaita kwararar ruwa a cikin masana'antar jiyya da tsarin karkatarwa. - Sarrafa sinadarai: Karɓar acid, alkalis, da kaushi yana buƙatar kayan da ba za su iya lalata ba.

- Oil & Gas: Bututun danyen mai, iskar gas, da hanyoyin tacewa.

- Tsarin HVAC: Yana sarrafa iska da kwararar ruwa a cikin hanyoyin dumama da sanyaya.

- Ƙarfafa wutar lantarki: Yana sarrafa tururi, ruwan sanyaya, da mai.

- Abinci & Abin sha: Tsarin tsafta don sarrafa ruwan aseptic.

- Pharmaceutical: Madaidaicin iko a cikin mahalli mara kyau.

- Marine & Pulp & Paper: Ana amfani da shi don ruwan teku, ɓangaren litattafan almara, da sarrafa sinadarai.

5. Fa'idodi da rashin Amfanin Flange Butterfly Valves

5.1 Fa'idodi:

- Karami da nauyi, rage farashin shigarwa da buƙatun sarari.

- Saurin aiki na kwata-kwata da saurin amsawa.

- Ƙananan farashi don manyan diamita.

- Rashin ƙarancin matsin lamba lokacin buɗewa, ingantaccen kuzari da inganci.

- Ya dace da sauyawar ruwa tare da kyakkyawan aikin rufewa.

- Sauƙi don kulawa da jituwa tare da tsarin sarrafa kansa.

5.2 Hasara:

- Fayil ɗin bawul yana toshe hanyar kwarara lokacin buɗewa, yana haifar da asarar matsa lamba. - Ƙarfin matsi mai iyaka a cikin aikace-aikacen matsi mai ƙarfi, mai yuwuwar haifar da cavitation.

- Kujerun bawul masu laushi suna sawa da sauri a cikin kafofin watsa labarai masu lalata.

- Rufewa da sauri na iya haifar da guduma na ruwa.

- Wasu ƙira suna buƙatar mafi girman juzu'i na farko, suna buƙatar masu kunna wuta masu ƙarfi.

6. Yadda Ake Sanya Butterfly Valve

A lokacin shigarwa, daidaita flange na bawul tare da flange na bututu, tabbatar da cewa ramukan kullu sun dace.

Saka gasket don rufewa.

Aminta da kusoshi da goro, ƙara matsewa daidai don hana murdiya.

Bawuloli biyu-flange suna buƙatar daidaita bangarorin biyu lokaci guda; Ana iya kulle bawul ɗin nau'in lugga ɗaya a lokaci ɗaya.

Bincika 'yancin motsi na diski ta yin hawan bawul ɗin kafin a matsa lamba.

Lokacin da aka shigar da shi a tsaye, ya kamata a sanya tushen bawul ɗin a kwance don hana tara ruwa.

Koyaushe bi jagororin masana'anta da ƙa'idodin gwaji kamar API 598.

7. Ka'idoji da Ka'idoji

Flanged malam buɗe ido bawulolidole ne ya bi ka'idodin aminci da haɗin kai:

- Zane: API 609, EN 593, ASME B16.34. - Gwajin: API 598, EN 12266-1, ISO 5208.

- Flanges: ASME B16.5, DIN, JIS.

- Takaddun shaida: CE, SIL3, API 607;(lafiya ta wuta).

8. Kwatanta da Sauran Bawuloli

Idan aka kwatanta da bawuloli na ƙofa, bawul ɗin malam buɗe ido suna aiki da sauri kuma suna ba da damar maƙarƙashiya, amma ba su da ɗan juriya don gudana.

Idan aka kwatanta da bawul ɗin ƙwallon ƙafa, sun fi ƙarfin tattalin arziƙi don manyan diamita, amma suna fuskantar asarar matsa lamba yayin buɗewa.

Bawuloli na Globe suna ba da ingantacciyar madaidaici, amma sun fi girma kuma sun fi tsada.

Gabaɗaya, bawul ɗin malam buɗe ido sun yi fice a cikin ƙarancin sarari da aikace-aikace masu tsada.